Leading Boron Grain Refiner Supplier in India: Metal Quality Optimized with Precision

In metallurgy, the properties and quality of metals are of utmost importance. Be it for automobile components, aircraft industry components, or overall manufacturing, the microstructure of the metal can have a profound effect on its strength, hardness, and functionality. Among the crucial factors that go a long way in enhancing the quality of metal is the application of grain refiners, more specifically boron grain refiners.

For industries seeking enhanced metal properties, partnering with a reliable boron grain refiner supplier in India can make all the difference. This blog will explore what boron grain refiners are, their importance, applications, and why sourcing them from a trusted supplier like Jagannath Company is essential for your manufacturing needs.

What is a Boron Grain Refiner?

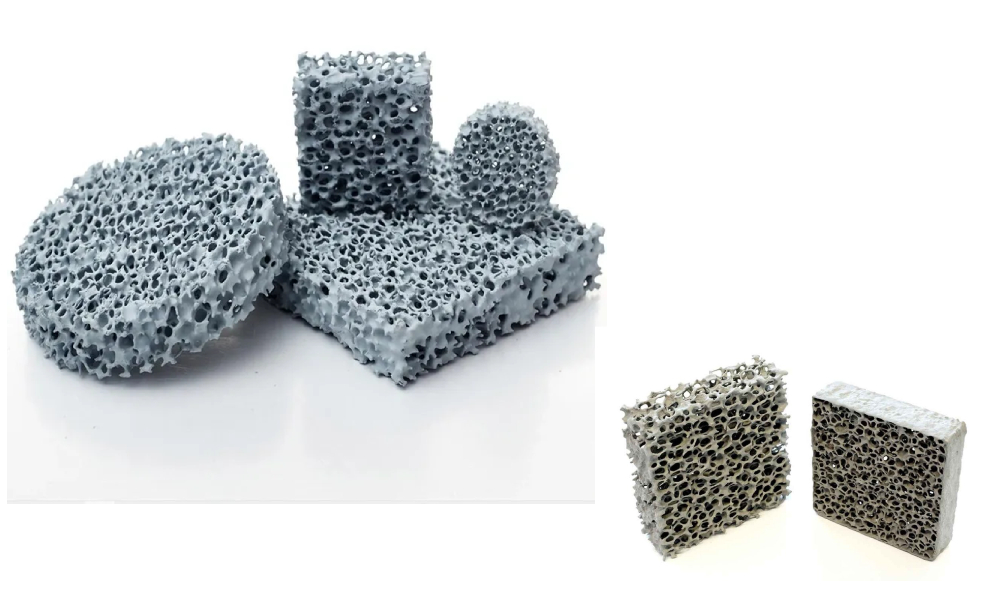

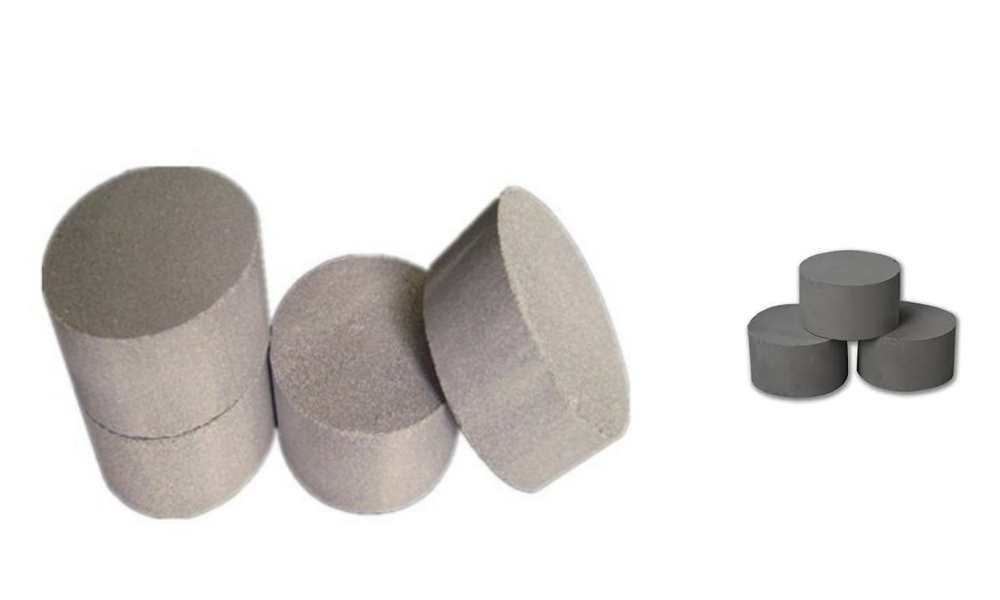

boron grain refiners are additives employed in metal casting and alloy production to regulate and refine the metal grain size, mostly aluminum and its alloys. Grain refinement refers to the creation of finer and more homogeneous grains in the metal structure that enhances mechanical properties like strength, toughness, and corrosion resistance.

The introduction of boron at the alloying step affects nucleation during solidification, assisting in the development of finer grains that improve the quality of the metal overall. As opposed to other grain refiners, boron is especially appreciated because it remains effective even at small concentrations, thus remaining cost-effective yet effective.

Why is Grain Refinement Important in Metallurgy?

Grain size directly affects metal properties. Coarse grains are responsible for creating weak points, thus the metals are more susceptible to cracking or failure when under stress. Fine grains, however, give the following:

- Increased tensile strength

- Enhanced ductility

- Enhanced fatigue resistance

- Increased corrosion resistance

- Smoother surface finish after machining

In safety- and performance-critical applications, like automotive engine parts or aerospace structures, grain refinement is absolutely necessary.

Applications of Boron Grain Refiners

Boron grain refiners have extensive applications in industries such as:

- Automotive Manufacturing: Engine blocks, transmission housings, and other essential components need strong and resilient metals. Boron grain refinement makes it possible for manufacturers to attain this.

- Aerospace Industry: Strong and lightweight alloys with fine grains provide safety and performance at high altitudes and under stress.

- Electrical Industry: Aluminum alloys with fine grains show improved conductivity and resilience in electrical products.

- Construction and Infrastructure: Grain refinement leads to durability and strength of building materials.

Why Opt for a Leading Boron Grain Refiner Supplier in India?

India is becoming a major force in the metallurgy and alloy production industry. It is important to select the right supplier so that you get high-quality grain refiners that are up to international standards. Why a good supplier matters:

1. Quality Assurance

A well-established supplier ensures quality checks for the boron grain refiners that are rigorous enough to ensure purity, efficacy, and consistency.

2. Customized Solutions

Various alloys and methods demand specific grain refining solutions. A qualified supplier can provide tailor-made formulations to suit particular production requirements.

3. Standard Compliance

Compliance with international standards like ISO guarantees that the materials supplied are safe and effective for industrial applications.

4. On-Time Delivery and Service

A reliable supplier has inventory and logistics in place to deliver products on time, reducing production downtime. They also provide technical services to maximize usage.

5. Cost Savings

Top-of-the-line grain refiners might appear to be an expense, but their impact on minimizing defects, increasing yield, and optimizing metal characteristics pays back handsomely in terms of cost savings.

How Boron Grain Refiners Work: The Science Behind It

During solidification of molten metal, grain refinement dictates the way crystals develop. Boron functions as a nucleating agent, promoting development of many small grains rather than one or two large ones.

The fine grains form a more homogeneous structure, enhancing strength and minimizing brittleness. This process also reduces defects such as porosity and hot tearing on casting, resulting in higher-quality end products.

Selecting the Ideal Boron Grain Refiner Supplier in India: What to Expect?

- Product Quality and Certification: Verify that the supplier offers boron grain refiners with tested purity and certification from prominent authorities.

- Technical Knowledge: The supplier must provide information on optimal usage levels, compatibility with various alloys, and processing conditions.

- Reputation and Testimonials of Customers: Testimonials from existing industrial customers can tell you about reliability and quality of services.

- Production Capacity: Facility to ship small as well as bulk orders according to your project needs.

- Post-Sales Support: Facility for troubleshooting, product modification, and regular supply.

Jagannath Company: A Name You Can Trust

In India's competitive metallurgy supply industry, Jagannath Company is a leading supplier of boron grain refiners. They are renowned for their quality, innovation, and customer focus, providing customized solutions to various industrial requirements. With decades of experience and rigid conformity to international standards, they are the preferred supplier for manufacturers requiring higher metal quality and performance.

Frequently Asked Questions (FAQs)

1. What is the proper dosage of boron grain refiner in aluminum alloys?

Ordinarily, between 0.01% and 0.05%, but the amount varies with the composition of the alloy and grain size to be achieved.

2. Are boron grain refiners suitable for all aluminum alloys?

Boron grain refiners are best suited with aluminum-silicon and other general-purpose alloys, but check with the supplier.

3. How does boron stack up against other grain refiners such as titanium or zirconium?

Boron is extremely effective at low levels and acts synergistically with other refiners, frequently increasing total grain refinement.

4. Is boron grain refining environmentally friendly?

Yes, boron is non-toxic in the minute amounts utilized for grain refinement and meets environmental safety regulations.

5. How long before I notice effects after introducing boron grain refiners?

Grain refinement effects are instantaneous upon solidification in casting or alloy processing.

Conclusion

Metal parts with high quality begin with first-class raw materials and accurate microstructure control. Boron grain refiners are a must-have to accomplish this, enhancing mechanical properties and prolonging product life.

By working with a reliable boron grain refiner supplier in India like Jagannath Company, industries can be assured that they are getting high-quality products coupled with expertise and service. Be it automotive, aerospace, electrical, or construction industries, boron grain refinement can take your manufacturing quality to global standards.